I-TEK Cameras

SWIR - Short-Wave Infrared

SWIR (Short-Wave Infrared) line scan cameras offer unique advantages for industrial inspection and various other applications by operating in the invisible SWIR spectrum (typically 0.9 to 1.7 or 2.5 micrometers). These benefits stem from how SWIR light interacts with materials compared to visible light, allowing for insights not possible with traditional cameras.

key benefits of SWIR line scan cameras:

- See Beyond Visible Light: SWIR cameras can detect features and “defects” that are difficult or impossible to distinguish with visible light. This is because certain materials, water vapor, and gasses become more or less reflective or transmissive in the SWIR range.

- Material Differentiation: SWIR imaging excels at differentiating between objects that appear similar in color in the visible spectrum. For example, it can distinguish between salt and sugar, or various types of plastics for recycling, based on their distinct reflective qualities in SWIR.

- Penetration Capabilities: SWIR light can penetrate certain materials that are opaque to visible light, such as silicon wafers, some types of packaging, and even ink (while not penetrating carbon traces, useful for banknote identification). This allows for inspection of internal structures or through protective layers.

- Imaging Through Obstacles: SWIR cameras can provide clearer images through atmospheric obscurants like haze, mist, smoke, and light fog due to less scattering of SWIR wavelengths. This makes them valuable for surveillance, outdoor applications, and challenging industrial environments.

- Moisture Detection: Water has strong absorption peaks in the SWIR spectrum. This property enables SWIR cameras to detect moisture content in materials, which is vital for applications in agriculture (crop health, fruit bruising), food inspection (spoilage), and manufacturing processes (drying monitoring for paper, pharmaceuticals).

- High-Temperature Detection: SWIR can detect heat signatures for objects above 300 degrees Celsius, making it useful for inspecting molten glass or metal for defects before they cool.

- High Resolution and Sensitivity: SWIR line scan cameras deliver high-resolution images, capturing fine details with clarity. Many models, including those from i-Tekvision, offer high sensitivity and low noise, crucial for demanding inspection tasks.

- Consistent Illumination and Distortion-Free Imaging: Similar to other line scan cameras, SWIR line scan cameras can provide homogeneously illuminated and distortion-free images, especially when inspecting continuous or cylindrical objects.

- Versatile Applications: The unique capabilities of SWIR line scan cameras make them invaluable in diverse industries, including:

-

Food Sorting and Quality Control: Detecting foreign objects, bruising, moisture content, and sorting products based on composition.

-

Recycling: Precisely sorting different types of plastics and other materials.

-

Semiconductor Industry: Inspecting silicon wafers for defects, cracks, and internal structures.

-

Pharmaceuticals: Monitoring drying processes and ensuring product quality.

-

Agriculture: Monitoring crop health and water absorption.

-

Printing and Textiles: Detecting defects and ensuring quality control on continuous materials.

-

Security and Surveillance: Day and night imaging, seeing through fog/haze, and detecting hidden lasers/beacons.

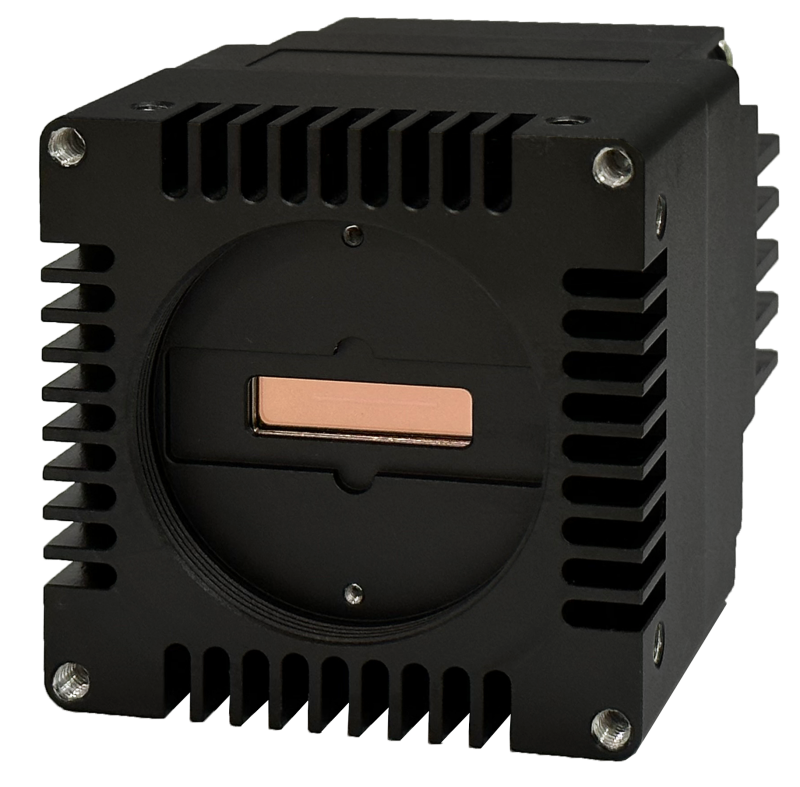

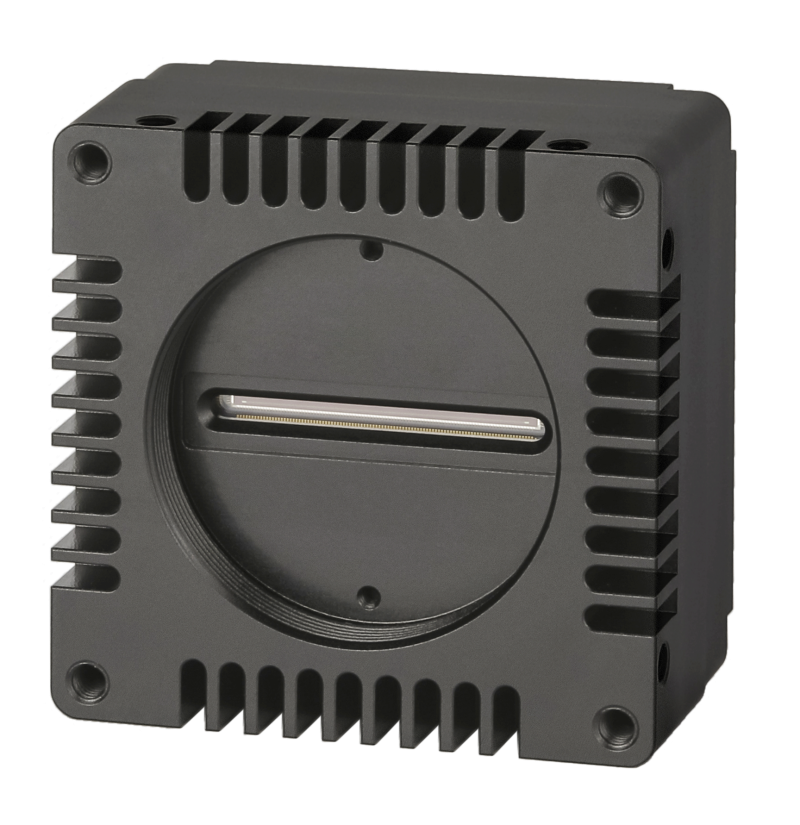

I-TEK 4K

Resolution 4K

-

Ultra-High Resolution (4K): With 4096 pixels across a single line, these cameras provide exceptional detail capture. This high resolution is critical for inspecting very fine features, small defects, or for applications requiring precise measurements over large areas, such as inspecting large display panels, printed materials, or components in the electronics industry.

-

High Speed and Throughput: I-TEK’s 4K line scan cameras are designed for high line rates, with some models capable of up to 250 kHz. This high speed enables efficient inspection of fast-moving continuous materials (webs) or discrete objects on a conveyor belt, ensuring no details are missed even in high-production environments.

-

Seamless and Distortion-Free Imaging: As line scan cameras, they capture images line by line as the object moves. This “stitching” method allows for theoretically infinite image length in the direction of motion, providing a seamless and distortion-free image of long or continuous materials like paper, fabric, metal sheets, or even cylindrical objects (when rotated).

-

Versatile Interface Options: I-TEK 4K line scan cameras support multiple high-speed data interfaces, including GigE, Camera Link, and CoaXPress. This ensures flexible integration into various machine vision systems and compatibility with different frame grabbers and software.

-

Monochrome and Color Options: I-TEK offers 4K line scan cameras in both monochrome and color modes. This versatility allows users to choose the appropriate model based on their application needs, whether it’s for general defect detection (monochrome) or detailed color analysis and sorting.

-

Advanced Image Processing Features: These cameras incorporate various algorithm processing technologies such as:

-

Binning: Combines pixel data to increase sensitivity or achieve higher frame rates at lower resolution.

-

Flat Field Correction: Corrects for uneven illumination or sensor non-uniformity, providing a more consistent image.

-

Disparity Correction: Useful in multi-line or 3D imaging applications to align images.

-

Spatial Correction: Helps in correcting geometric distortions.

-

High Sensitivity and Low Noise: Essential for capturing clear images even in challenging lighting conditions or when subtle details need to be highlighted.

-

-

Robust and Compact Design: I-TEK’s cameras often feature a modular and compact design, making them easier to integrate into existing industrial setups or into systems with multiple cameras. They are built for stable operation in industrial environments.