IN-Sight 3800

Maximizes Throughput: With twice the processing power of previous systems, it enables more inspections in less time, thanks to its high-speed processing and quick setup.

Improves Accuracy: It generates high-contrast, high-resolution images that are crucial for detecting even subtle defects, ensuring higher quality control.

Flexible and Scalable

Automation:

Accessible AI: Features innovative edge learning technology, making AI-powered automation accessible for both beginners and experts through example-based training.

Comprehensive Toolset: Includes a full set of rule-based tools that can be used independently or combined with AI for complex tasks like measuring, counting, code reading, and robot guidance.

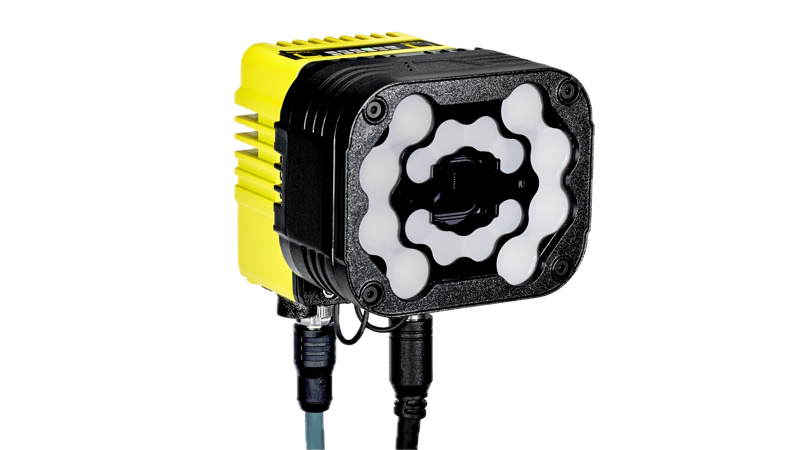

Superior Image Formation:

Optimized Contrast: Utilizes powerful image formation with multi-color lighting (RGBW and IR) and advanced illumination for long-range applications, which optimizes contrast.

Faster Line Speeds: HDR+ technology enhances image contrast and detail, simultaneously reducing exposure times, which is essential for faster production lines.

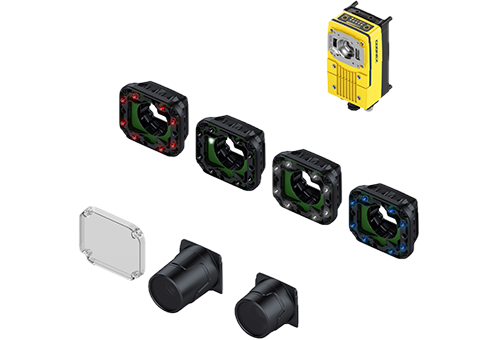

Flexible Development and Hardware:

User-Friendly Software: The In-Sight Vision Suite software offers both the intuitive EasyBuilder for simple tasks and a robust spreadsheet interface for more complex applications.

Adaptable Hardware: Its scalable modular hardware design can be adapted to evolving needs and various application settings, providing long-term value.

In-Sight 2800

-

Increases Product Quality: By combining AI with traditional rule-based vision tools, it optimizes error detection, allowing for the identification of subtle defects. It supports unlimited classification outputs and regions of interest, enabling detailed categorization of defects and accurate identification of parts with variations.

-

Maximizes Operational Efficiency: Designed for easy deployment, it requires no programming experience. Its intuitive EasyBuilder development environment provides step-by-step guidance, leading to quick setup and rapid deployment, which helps manufacturers leverage their existing workforce and maintain smooth production.

-

Streamlines Integration: The system simplifies image optimization and accessory identification. It features powerful, flexible integrated multi-color lighting (RGBW) for optimal image formation, maximizing contrast and illumination. High Dynamic Range (HDR) Technology further enhances image quality and contrast for more accurate inspections.

-

Offers Modularity and Scalability: With field-changeable components, the In-Sight 2800 allows manufacturers to quickly adapt to new parts and evolving demands, ensuring the system remains relevant for current and future needs.

In-Sight SnAPP Vision Sensor

-

Accurate Detection: It utilizes pre-trained AI to provide high accuracy and performance, surpassing conventional sensors. It can find subtle anomalies, eliminate false positives/negatives, handle variations, and precisely locate features and parts regardless of their position.

-

High Ease of Use and Fast Deployment: This sensor is designed for quick and easy application setup with no prior experience required. Its guided setup and browser-based user interface allow operation from anywhere, and jobs can be trained efficiently with just a few sample images. Modifications can be made easily through the UI without needing hardware exchange.

-

Flexible Capability: The In-Sight SnAPP can address a wide range of inspection tasks, from simple presence/absence detection to comprehensive quality inspections. Its intuitive user interface allows for the creation of new jobs, enabling automation of more steps in the production process.

-

Cost Reduction and Efficiency: By automating tasks and allowing quick changes even after installation, it helps businesses remain agile, reduce operational costs, increase efficiency, and eliminate manual errors. Its web-based UI or VisionView display panel simplifies device management and enables real-time process improvements.

-

Compact Size and Robust Design: Its compact form factor facilitates easy integration of automation anywhere in a facility. Additionally, its IP67 rating ensures reliable operation even in demanding manufacturing environments.

In-Sight D900 Vision System

AI-Based Automation: It leverages both edge learning and deep learning tools, making advanced AI capabilities accessible even to non-programmers for tasks like defect detection, assembly verification, and optical character recognition (OCR).

On-Device Processing: Processing occurs directly on the device, eliminating the need for a separate PC, which simplifies deployment and integration.

Enhanced Optical Character Recognition (OCR): The system can reliably decipher badly deformed or poorly etched codes using a pre-trained font library, significantly reducing development time for OCR applications.

Reliable Assembly Verification: It effectively detects complex features and objects, ensuring correct assembly even when components vary in angle or size.

Superior Defect Detection: The In-Sight D900 excels at identifying subtle and unpredictable defects on complex parts and surfaces. Its classify tool utilizes AI to sort defects and distinguish between true defects and acceptable abnormalities.

Ease of Use with Edge Learning: The embedded edge learning tools are simple to set up, require smaller image sets, and can be trained in minutes with minimal images and no coding, accelerating deployment.

Hardware Modularity and Intuitive Interface: It features hardware modularity with field-changeable components, offering adaptability. An intuitive web-based Human-Machine Interface (HMI) further simplifies training and deployment.

In-Sight 8000 Series Vision

-

Ultra-Compact Design for Easy Integration: With dimensions of just and Power over Ethernet (POE) capability, these systems are ideally suited for integration into tight spaces, including directly on robots or other machinery in hard-to-reach areas of a production line.

-

Industry-Leading Vision Tool Performance: Despite their small footprint, they deliver exceptional vision tool performance, supporting resolutions up to 5 megapixels, which is critical for detailed inspections.

-

High-Speed Communication: Equipped with Gigabit Ethernet, they facilitate fast image acquisition and data transfer, crucial for maintaining high production line speeds.

-

Ease of Deployment and Maintenance: The systems are easy to deploy and maintain using the In-Sight Explorer software. This software combines a guided setup process with the flexibility of a spreadsheet interface, offering both simplicity for beginners and extensive control for advanced users to customize application data.

-

Ensured Production Line Efficiency: Features such as TestRun system validation and the Cognex Connect suite help ensure that production lines operate smoothly, on schedule, and at full throughput, minimizing downtime and maximizing productivity.

In-Sight 9000 Series Vision System

-

Ultra-High Resolution for Precise Inspection: These systems offer ultra-high resolution capabilities, enabling accurate part location, measurement, and inspection over large areas, even from a distance. This feature also allows for safer mounting away from hazardous equipment.

-

Simplified Multi-Camera Applications: A significant advantage is its ability to serve as a single-camera solution for tasks that would typically demand multiple cameras. This reduces complexity, minimizes calibration requirements, and lowers overall system costs.

-

Robust and Self-Contained Design: Housed in a self-contained, IP67-rated enclosure, the system is protected from liquids and dust. This eliminates the need for external enclosures and simplifies installation, especially in space-constrained production lines.

-

Easy Configuration Without Programming: The In-Sight EasyBuilder interface guides users through setup, allowing for full configuration of the system without the need for complex programming.

-

Industry-Leading Vision Tools: The series includes advanced vision tools such as PatMax RedLine, known for its fast and accurate 2D pattern matching. Additionally, the In-Sight 9912 model features HDR+ technology for enhanced image contrast without compromising acquisition speed.

-

Flexible Scanning Options: The series offers both line scan (e.g., 9902L) and area scan (e.g., 9912) models, providing versatility for inspecting continuously moving objects or large, stationary parts with high speed and detail.